|

|

Our CREST-FX folder gluer can be fitted to any top print flexo unit,

in order to integrate with a new flexo printer to compose an FFG.

In addition, existing FFGs can even be retrofitted to improve folder gluer capabilities and folding quality.

Wise users who want to avoid reject value-added blanks due to folding irregularity and fishtailing,

choose Oshitani,

the specialists in folder gluers.

|

|

|

| Promotional Video Released! |

|

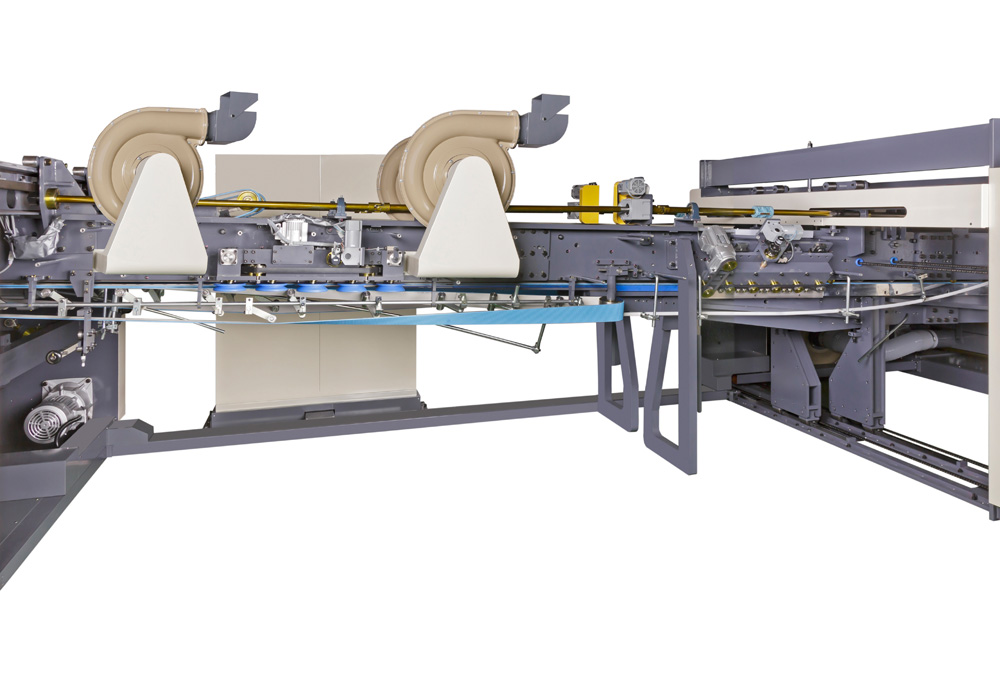

1.Blank Catching Section |

|

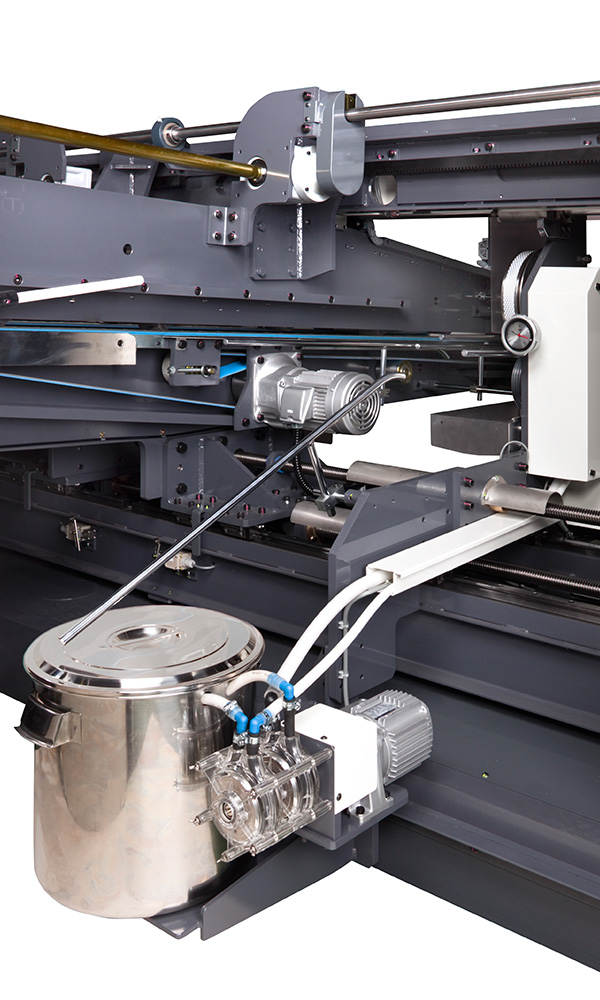

2.Glue Unit

|

|

Upper and Lower Belt Clearance Adjustment

- →Automatic clearance set according to flute.

- →Straight blank transfer from flexo printer's slotter section.

|

|

|

|

Tubing Pump

- →Easy maintenance (replace tubes periodically).

- →Low maintenance costs.

Glue Circulation System

- →Less glue consumption. Excess glue is returned to the tank.

Glue Tank with Thermostat

- →Stable glue viscosity even in cold weather.

|

|

3.Folding Section |

|

4.Counter-Ejector Section

(“One-Stage Downstacking”-type) |

|

"SuperMax" Innovative Folding System - inner and outer ring assembly

→Accurate folding along the crease line.

→Dramatic improvement in folding accuracy.

Side Forming Rollers

→5 forming rollers on each side of folding rail to prevent fish-tailing.

Reinforcement Frames (50mm thickness)

→Connecting upper & lower folding rails to minimize vibration of lower rail.

Main Belt Vacuum Transfer

→Prevents skewed travel of blanks in the folding area.

Strengthened Rigidity of the Folding Rail

→Reinforced support and ribs eliminate vibration of the lower folding rail caused by passing blanks.

Speed-Adjustable Folding Assist Belt

→Suitable belt speed can be selected according to panel length and width.

|

|

|

|

|

High Speed Operation

→High speed, stable operation for small-size boxes.

Handles a Diversity of FFG Boxes

→RSC with hand holes, die-cut shapes and outside glued cases can be accurately batch counted. (Note that there are limits on the die-cut shape and folding size of the outside glued case.).

Safety

→Door with interlock prevents accidents during operation.

|

|

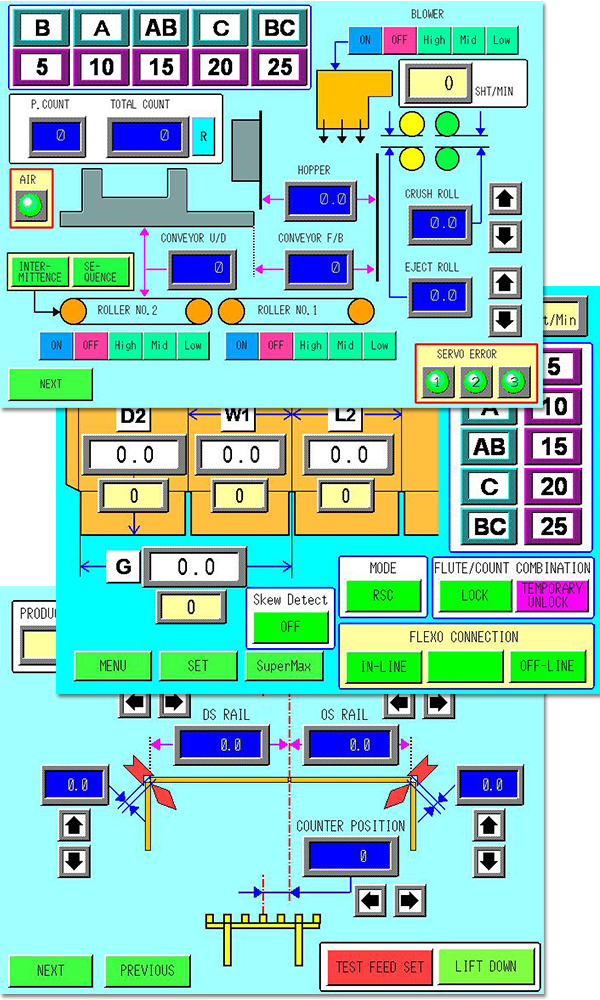

5.Control Panels |

|

|

|

Color Touch Screen (Feeding and counting sections)

→Quick and simple setup.

→Indicates operating status and alarms.

→User-friendly interface.

Web Server Module (option)

* Requires a LAN network

→Monitoring of PLC operating status and updates/modification to the operation program possible over the Internet.

|

|

|

|

SPECIFICATIONS |

|

|

|

| Total Machine Length |

Approx. 13.0m |

| Total Machine Weight |

Approx. 16.0t |

| Power Requirements |

40kW (AC200V), 50/60Hz, 3P, 200A |

| Air Flow Rate |

380L/min. |

| Flute |

A, B, C, AB, BC |

| Counts per Bundle |

| B flute |

10, 15, 20, 25 |

| A, C flute |

5, 10, 15, 20 |

| AB, BC flute |

5, 10 |

|

* When 5 counts/bundle is selected, production speed should be less than 75 sheets/min. |

|

|

| Machine Size |

2.1 type |

2.4 type |

2.7 type |

| Max. Speed |

300 sheets/min. |

300 sheets/min. |

200 sheets/min. |

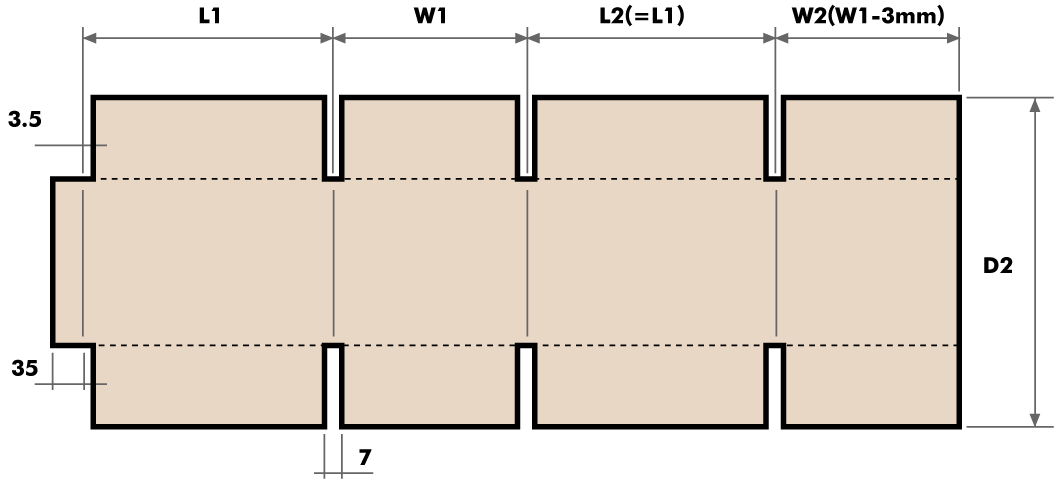

| Side Panel (L2) |

Max. |

775 |

825 |

900 |

| Min. |

175 |

175 |

200 |

| End Panel (W1) |

Max. |

525 |

600 |

675 |

| Min. |

130 |

130 |

130 |

| L2 + W1 |

Max. |

1050 |

1200 |

1350 |

| Min. |

305 |

305 |

330 |

| Sheet Width (D2) |

Max. |

650 |

800 |

1240 |

| Min. |

200 |

260 |

280 |

| Glue Flap Width (G) |

35 |

35 |

35 |

|

|

Copyright(C) 2017 Oshitani Manufacturing Co., Ltd. All rights reserved.