|

|

The industry needs to avoid reject value-added blanks due to folding irregularity and fishtailing.

Oshitani thus focuses on folding quality, believing that to ultimately be the most critical issue facing this industry.

Deeper, larger cases are always difficult to produce, especially for users who are very meticulous about folding accuracy, so we have been listening to a wide range of production staff and have developed a method to ensure folding quality using an outside and inside wheel assembly guide (patent pending) that folds blanks correctly.

|

|

|

| Promotional Video Released! |

|

1.Feeding Section |

|

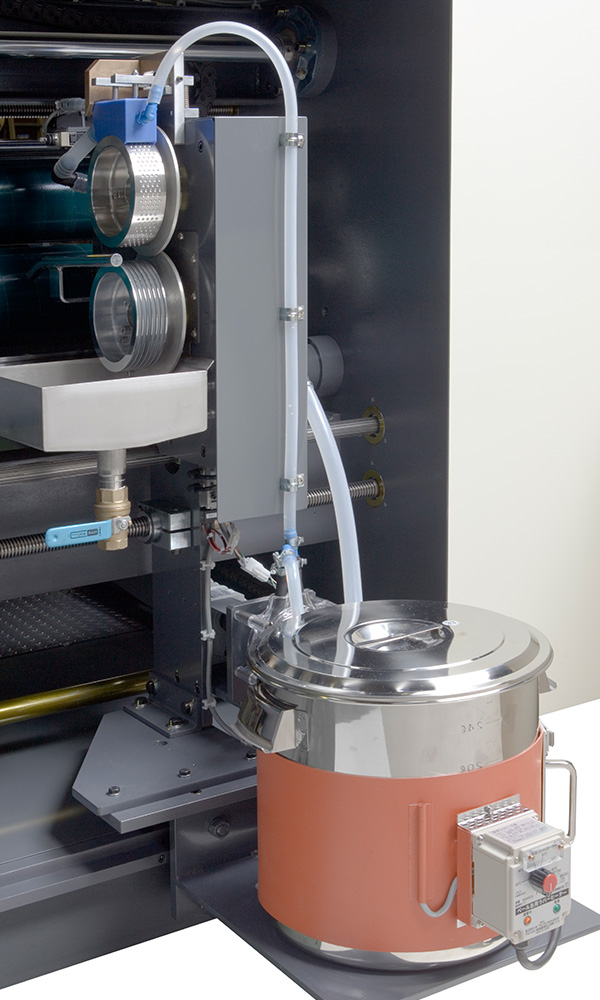

2.Glue Unit |

|

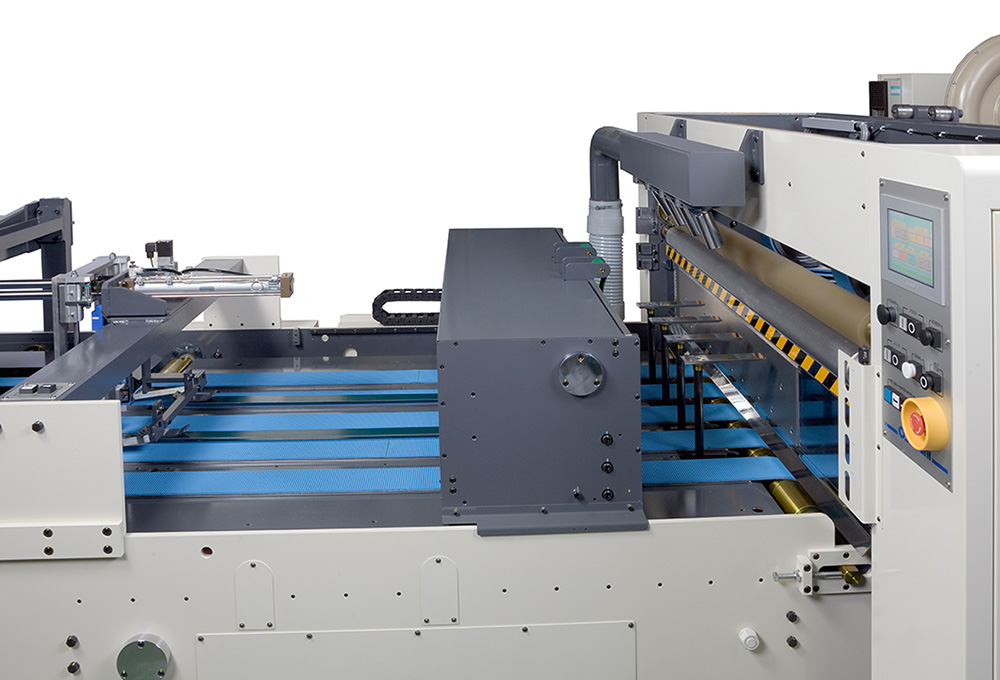

Suction Belt Feeder

→Straight blank transfer to Folding Section.

|

|

|

|

Tubing Pump

→Easy maintenance.

(replace tubes periodically)

→Low maintenance costs.

Glue Circulation System

→Less glue consumption. Excess glue is returned to the tank.

Glue Tank with Thermostat

→Stable glue viscosity even in cold weather.

|

|

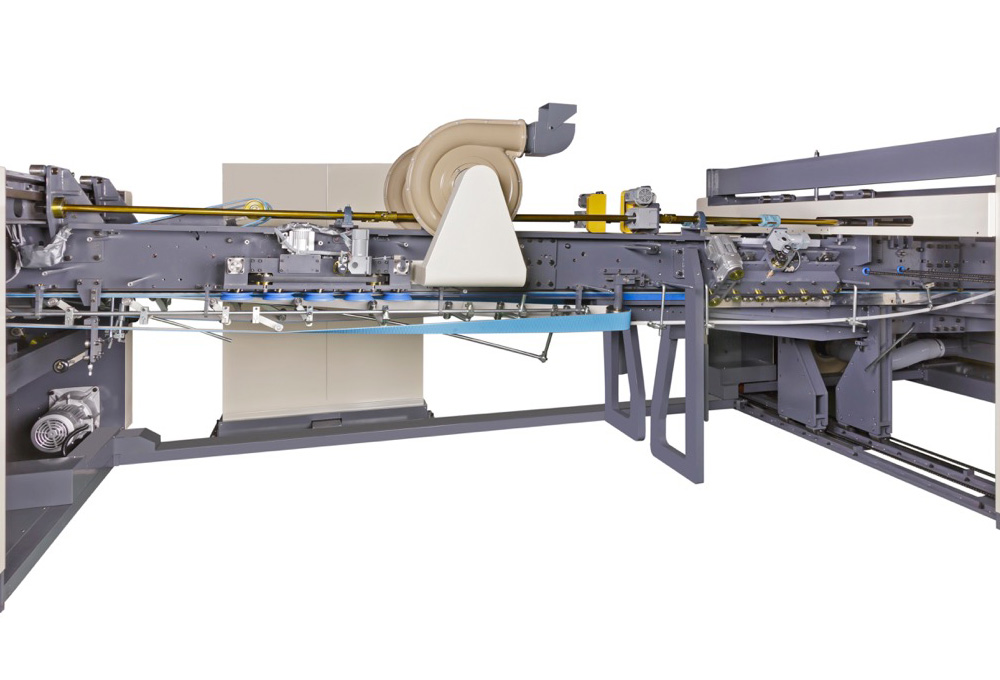

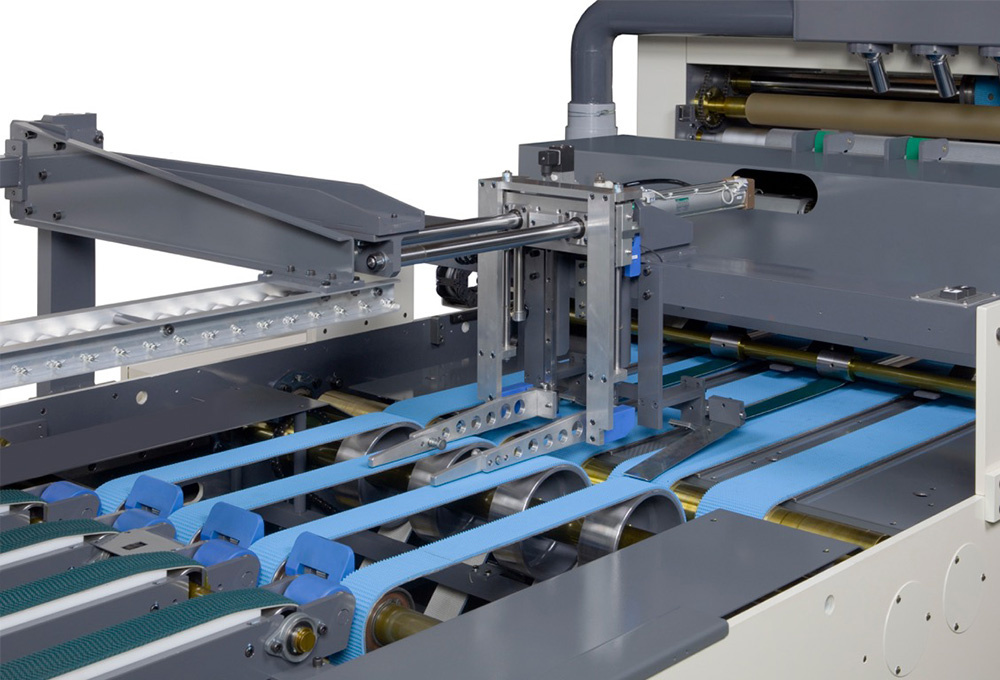

3.Folding Section |

|

4.Hopper Squaring Section |

|

"SuperMax" Innovative Folding System - inner and outer ring assembly

→Accurate folding along the crease line.

→Dramatic improvement in folding accuracy.

Side Forming Rollers

→5 forming rollers on each side of folding rail to prevent fish-tailing.

Reinforcement Frames (50mm thickness)

→Connecting upper & lower folding rails to minimize vibration of lower rail.

Main Belt Vacuum Transfer

→Prevents skewed travel of blanks in the folding area.

Strengthened Rigidity of the Folding Rail

→Reinforced support and ribs eliminate vibration of the lower folding rail caused by passing blanks.

Speed-Adjustable Folding Assist Belt

→Suitable belt speed can be selected according to panel length and width.

|

|

|

|

Blank Catching Elevator

→Catches all incoming blanks securely for stabilization in the hopper squaring section.

Air Blower

→Air direction can be adjusted freely for stable securing of even large, springy boxes in the squaring section.

|

|

5.Counter Section |

|

6.Control Panels |

|

Understack Counting System

→Suitable for high speed operation.

→Aids in sufficient curing of applied glue even with small, springy blanks. |

|

|

|

Color Touch Screen (Feeding and squaring sections)

→Quick and simple setup.

→Indicates operating status and alarms.

→User-friendly interface.

Web Server Module (option)

* Requires a LAN network

→Monitoring of PLC operating status and updates/modification to the operation program possible over the Internet.

|

|

SPECIFICATIONS |

|

|

|

| Max. belt speed |

120 m/min |

| Total machine length |

(Type-2700)13,535mm

(Type-3000)14,485mm |

| Total machine weight |

(Type-2700) Approx.13.0ton

(Type-3000) Approx.14.0ton |

| Power requirements |

25kW (AC200V), 50/60Hz, 3P, 125A |

| Airflow rate |

100L/min. |

| Flute |

A, B, C, AB, BC |

| Counts per bundle |

| B flute |

10, 15, 20, 25 |

Max.

batch height: 250 mm

Min.

batch height: 75 mm |

| A, C flute |

5, 10, 15, 20 |

| AB, BC flute |

5, 10 |

|

|

|

| Size |

Type-2700 |

Type-3000 |

| Side panel (L2) |

Max |

900 |

1000 |

| Min |

200 |

200 |

| End panel (W1) |

Max |

675 |

750 |

| Min |

130 |

130 |

| L2 + W1 |

Max |

1350 |

1500 |

| Min |

330 |

330 |

| Sheet width (D2) |

Max |

1240 |

1400 |

| Min |

280 |

280 |

| Glue flap width (G) |

35 |

35 |

| |

|

|

* The side panel (L) should be longer than the end panel (W).

* When 5 counts/bundle is selected, production speed should be less than 75 sheets/min.

|

Copyright(C) 2017 Oshitani Manufacturing Co., Ltd. All rights reserved.